RÉMI TAFFIN, DIRECTOR OF OPERATIONS

In Malaysia we got close to what we would consider the normal level of driveability we had at the end of 2014. For China we will have some small steps forward. We have continued the intensive test program started after Australia and we will see further results in Shanghai. Performance was likewise an improvement in Malaysia, although we did keep some in reserve to safeguard reliability.

Now we are getting more confident in this area we can afford to be more aggressive and we should see better results on the straights, with a higher top speed. We finished in 7th, 8th, 9th and 10th in Malaysia and with the improvements put in place we hope to be further up.

Toro Rosso has shown it has a good basic car and the drivers are confident, while Red Bull should be on top of the issues experienced in Malaysia. With the improvements to driveability and overall performance, we hope we can fight the Williams’ cars and grab some more points in China.

POWER UNIT DETAILS

ICE

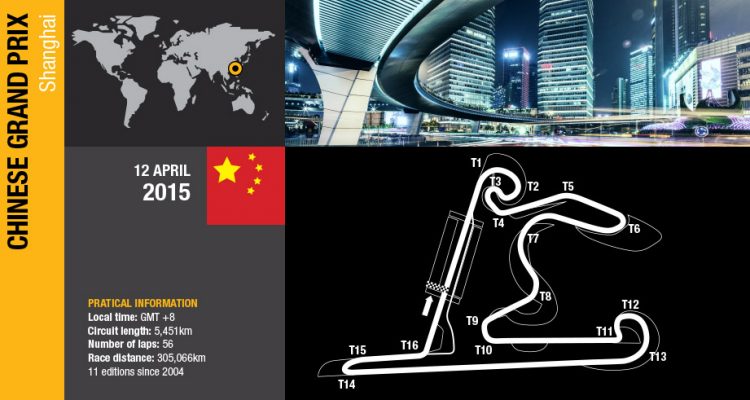

The 1.3km back straight is one of the key characteristics of the Shanghai circuit. Down the straight the ICE will be at maximum revs and wide open throttle for 20secs, or approximately 20% of the lap.

The pit straight is also 700m long. This, and several other short bursts of full power, bring the total percentage of wide open throttle time to over 50% of one lap.

The average speed over a lap will be 200kph, putting Shanghai in the middle of the table for lap speeds.

Race fuel saving will be low, one of the easiest tracks of the year in this respect.

TURBOCHARGER

The first corner complex and mirror-image Turn 11 – 13 complexes see the track tighten back on itself, with the driver braking down and shifting down through the gears. The turbo needs to deliver a consistent level of boost through the complexes to allow reactive gear changes and rapid responses on the exits.

Down the two long straights the turbo will be rotating at over 85,000rpm to provide the correct amount of air to the ICE whilst being able to recover a maximum amount of energy with the MGU-H.

MGU-K

During the first corner complex the driver will be on the brakes for some 3secs, providing a good opportunity to recharge the battery via the MGU-K.

The Turn 11 – 13 complex is a mirror image of the first corner and the driver will again be on the brakes for another 2secs, thereby giving another significant opportunity to recharge the battery.

The hairpin at the end of the straight requires the cars to brake from over 320kph to just 60kph. The energy going through the brakes at this point will be massive – an average of 700kW over the 3secs braking distance. In fact, approx. one quarter of the energy recovered via the MGU-K under braking will be recovered at this point.

The driver will be braking for roughly 19% of the lap, or 19secs.

MGU-H

A large percentage of the wide open throttle time is concentrated into the pit straight and the back straight, meaning the MGU-H has a lot of opportunity to recover energy through the exhaust gasses.

The flowing sector two also sees a steady stream of exhaust. Shanghai is one of the most efficient circuits in this respect, and close to the maximum amount of energy will be stored in the battery per lap. This will allow us to optimize the amount of energy transferred directly from the H to the K or to the battery.

This in turn maximizes the potential of the K to recover energy over a race lap and, therefore, improve car performance. This is especially important in sector three, which is primarily influenced by engine power.

RENAULT 2015 FAST FACTS

Ambient temperatures in Shanghai can be variable and there has been a variation of +/-10°C over the past ten years. Temperatures can even oscillate drastically over the course of the weekend, with a variant of around 5°C at some points. While lower temperatures mean a greater engine power output, the changes in ambient conditions can affect the amount of knock, which the engineers will need to carefully monitor.

The Shanghai International Circuit is an exposed track, influenced by wind speed and direction. The main problem is usually T14, with the rest of the track a bit more sheltered. A head wind down the main straight will affect the top speed of the car and must be taken into account when assessing the performance of the engines.

The location of the Shanghai track also provides an unusual challenge. The circuit is situated in an industrial zone next to several factories, some of which produce concrete, which leads to a high concentration of dust particles in the air. It is important to have a good air filter to prevent damage to the turbo compressor and ICE.

When a driver applies the DRS on a straight, the amount of drag created by the rear wing is suddenly reduced. This means that for the same engine power the car accelerates more and reaches a higher top speed. Engineers estimate that the application of the DRS will result in an RPM increase of up to 800RPM at the end of the straight.

FOCUS ON…CHINESE GP 2009

The rain-soaked Chinese GP of 2009 could be called a watershed moment in modern F1. Until that point the Red Bull Racing-Renault team had been gaining momentum, but it was in Shanghai that the team secured its first pole and victory. Sebastian Vettel took the chequered flag, with Mark Webber second, ushering in a new era of team domination for the sport.

Thierry Salvi, track support leader for Infiniti Red Bull Racing, remembers the race. ‘In 2009 I was Fernando Alonso’s engine engineer, working trackside for Renault F1 Team. In the previous couple of races, Red Bull had been strong and challenging for the podiums and when we got to China they were quick again and in quali Seb was ahead of Fernando by two tenths. You don’t do well in qualifying by chance, especially in the rain and we knew that the team was going to be on it in the race.

‘Come Sunday, Sebastian and Mark were miles ahead of everyone, even with the difficult conditions. For us in Renault F1 Team colours, it was hard to see a client team finish ahead, but motivating at the same time. We’ve always had a competitive spirit in Viry, and we wanted to get back ahead of our colleagues!

‘With our Viry hat though, it was fantastic that another team using our engines had win. We’d worked very hard to bring the V8 engine back to the level of 2006 when we had some margin of superiority. China is also especially hard for an engine supplier and that we could power a team to a 1-2 was very satisfying. It also showed we’d adapted the engine to another chassis and done it well.

‘China was really the start of the Red Bull era,’ remembers Thierry. ‘We had started to supply them in 2007 and in just two years they had gone from a relatively small midfield team to race winners. It was an enormous step. The feeling at Viry was that they were to be taken seriously and had serious ambitions.

‘I took over the trackside operations in 2013 and the pressure was huge – they had won three titles by then and wanted to keep winning. Joining a team with a winning advantage and keeping ahead is a very different type of pressure than joining at the start with nothing to lose. That ambition is still very much there.’